Download the Case Study

A typical processing plant has hundreds, or even thousands, of pumps which can consume up to 60% of the facility's energy usage. A major oil and gas company partnered with Flowserve to address potential energy cost savings at one of its facilities.

Download our technical article to see how we calculated hidden costs and proposed solutions that would result in 35% annual savings.

Optimizing pump wire-to-wire efficiency can be an important consideration toward the achievement of energy transition goals. The Flowserve Energy Advantage Program offers you a suite of solutions which can enable significant efficiency gains from the optimization of pump and valve energy consumption and effective recapture of wasted energy.

Flowserve has an unrivaled combination of technical expertise and practical experience to lead you through the transition.

The Flowserve Energy Advantage Program is a holistic flow control approach aimed at helping you reach your carbon reduction goals and lowering your total cost of ownership (TCO). It provides you with Flowserve’s engineering expertise, a systematic data-driven evaluation process, and a complete offering of proven products and services that can drive increased energy efficiency through the optimization of pump and valve power consumption. Flowserve’s offerings through the Energy Advantage Program can also reduce your carbon emissions, improve plant productivity and reliability, and provide operational savings.

Significant efficiency gains from the optimization of energy consumption and recapture of wasted energy.

Cost-effective tailored solutions focused on reducing hydrocarbon and GHG emissions.

Solutions for increased equipment reliability, reduced maintenance spend, and optimized operational expenses.

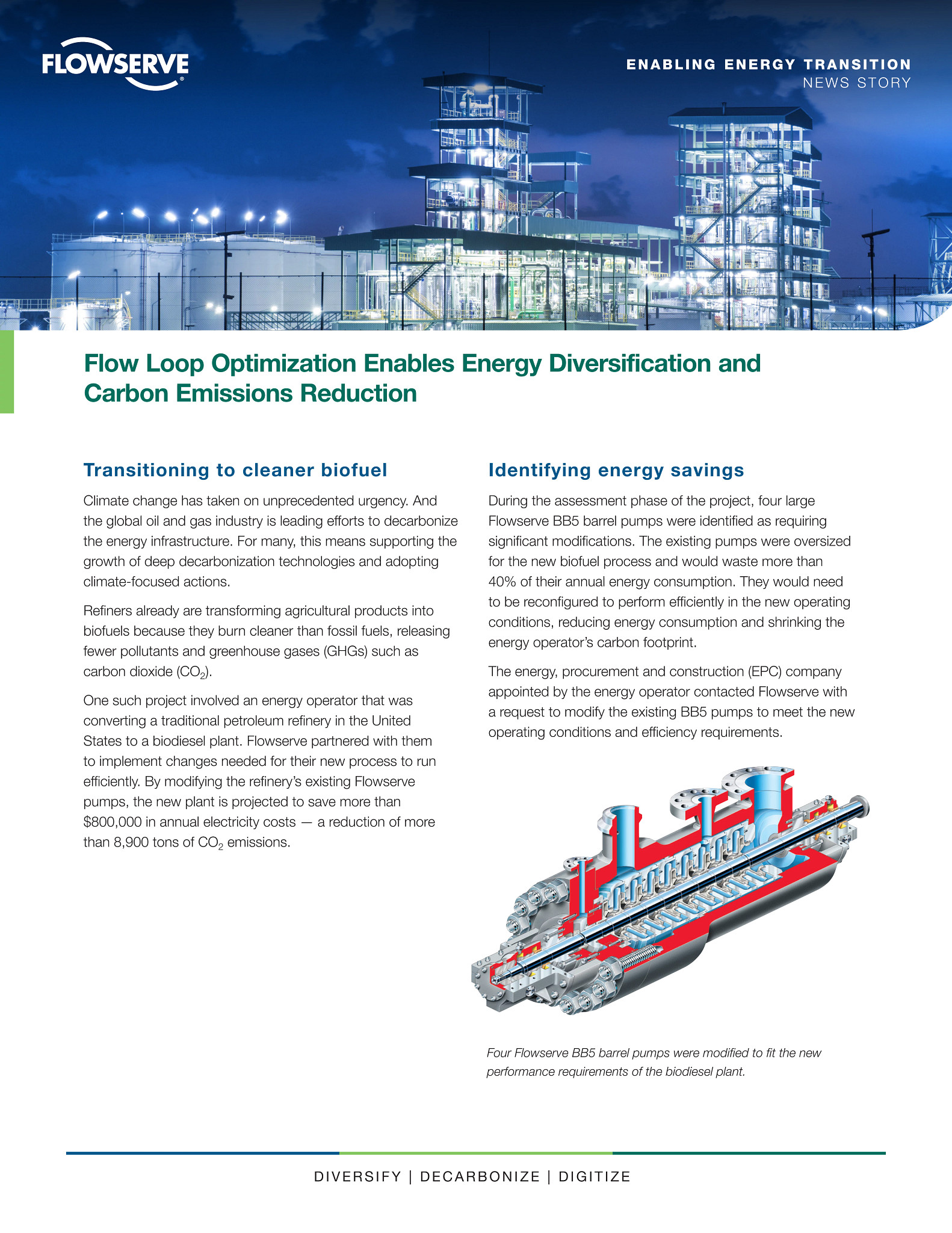

See how Flowserve's focus on energy efficiency delivered significant cost savings and emissions reduction for a large plant.

Get the news story.